Pharmaceutical Manufacturing Equipment

Manufacturing equipment for wet & dry granulation, milling and blending pharmaceutical powders.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

Wet Granulation

The most commonly used method for producing Pharmaceutical OSD products.

IDEX MPT supplies equipment that conditions powders, improving their flowability & compressibility. Creating stronger, more uniform tablets, reduced dust and better dissolution

rates.

Dry Granulation

A granulation method ideal for moisture & heat sensitive materials. It offers a lean, efficient way to condition powders, using less equipment & process steps.

IDEX MPT offers Roll Compaction with integrated milling from lab scale to pilot and on to large scale production sized equipment.

Tablet Handling

Materials handling, of powders or tablets, is critical in ensuring product quality and integrity. Correct handling prevents contamination risks and safeguards the workforce.

IDEX MPT offers stainless steel IBCs for transferring & processing powders, along with HDPE IBCs for the gentle handling of tablets.

Why Us

Across the IDEX MPT group, we are specialists in powder handling and particle processing. Our brands are recognized for offering well-designed equipment solutions to leading pharmaceutical manufacturers. Driven by the IDEX values of trust, team, and excellence, our teams utilize creative problem-solving and collaboration to guide our global customers towards their objectives.

Each product in our portfolio is designed and manufactured to high standards of materials, finish, and performance. Our equipment is efficient, reliable, and compliant to the rigorous sector standards, so you can trust in our brands to deliver safe, durable solutions with lasting value.

Global Coverage

Multiple locations around the world allow us to serve customers globally.

Integrated Teams

The IDEX MPT brands are united to provide you with comprehensive solutions.

Trusted Solutions

Our brands are tested, used & trusted by leading manufacturers worldwide.

Years of Expertise

Many of our brands have been providing pharmaceutical solutions for over 40 years.

Wet Granulation

Advanced milling and sizing solutions for pharmaceutical OSD powders.

Wet granulation is a widely used method in OSD as it improves the flowability, compressibility and bulk density of pharmaceutical powders in order to produce tablets, capsules, and sachets that are consistent in weight, contain the target % of API & excipient in each dose with content uniformity (CU), and have the correct bioavailability for a therapeutic dose.

Over the decades, the Quadro brand has supplied mills that deliver precise, reliable particle size reduction for the three key stages in the wet granulation process:

- Screening, Delumping & Milling

- Wet Milling / Wet Mass Delumping

- Dry Milling / Calibrating

Each mill is designed to meet strict pharmaceutical quality and cGMP standards, ensuring reliable performance and consistent product quality. Quadro offers scalable solutions from the lab to production, which maximize efficiency, minimize waste, and ensure powders are consistently prepared to meet OSD production targets.

To learn more about how Quadro equipment supports the wet granulation process, visit the Quadro brand website via the button below.

.png)

The Quadro Product Range

The Quadro® FlexSift

The Quadro® FlexSift offers fast, secure screening at range of capacities with high product recovery to minimize waste.

It effectively deagglomerates raw materials whilst capturing and retaining impurities to prevent contamination.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

The SDx™ Series

The SDx™ is a scalable solution that offers multiple size reduction solutions on one platform.

Built-in SMARTdetect™ technology recognizes which head is installed and adjusts the RPM automatically to efficiency and ease-of-use.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

Scalable Lab System

The SLS is a benchtop powder milling and screening platform offering five milling, size reduction, and processing solutions.

It streamlines development with interchangeable heads, versatile screen and impeller options, and seamless scalability to production.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

Dry Granulation

Delivering lean, efficient roll compaction equipment for pharmaceutical dry granulation processing.

Dry granulation converts fine powders into larger, free-flowing granules without the need for liquid binders or drying steps. Powders are compacted into dense ribbons, which are then milled into uniform particles. The result is improved powder flow, easier handling and enhanced tableting performance, making dry granulation an efficient choice for moisture-sensitive and heat-sensitive materials.

Manufacturers worldwide choose the Fitzpatrick brand as it is recognized for its reliability, process consistency and system design. With a scalable range of solutions, from lab-scale to production-scale systems, customers find the ideal fit for every stage of development & manufacturing. Process flexibility is further assured with the ability to alternate between knife or bar rotor, along with an extensive range of screens for the hammer mill.

To learn more about Fitzpatrick's roll compaction equipment for the pharmaceutical industry, visit the Fitzpatrick brand website via the button below.

The Fitzpatrick Product Range

Lab Compaction System

The LCS offers precise benchtop dry granulation with a space-saving design, ideal for process development and trials. Results achieved at this scale can be repeated at larger volumes.

The LCS is easy to operate and clean, helping researchers and formulators evaluate granulation techniques and optimize processes before moving to full-scale manufacturing.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

CCS - Pilot-Scale

The Fitzpatrick Pilot-Scale CCS Series is ideal for R&D and proof-of-concept research. The unique dual-screw feed system design ensures the ideal conditions are created right from the outset.

All CCS models share the same design, making it easier for cleaning and maintenance as knowledge is completely transferable when you scale up to larger volumes.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

.webp?width=525&height=350&name=CCS720-002-_1_%20(1).webp)

CCS - Production-Scale

The Fitzpatrick CCS1025 is designed for precise control and high-capacity production in dry granulation. Results achieved at lab- and pilot-scale can be achieved at larger capacities with this equipment.

Its robust construction and scalability make it suitable for large-scale pharmaceutical manufacturing.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

Powder and Tablet Handling

IBC systems for efficient and gentle handling of pharmaceutical powders and tablets.

Matcon IBC systems are designed to help pharmaceutical manufacturers improve both productivity and product quality whilst adhering to strict regulatory requirements. Common powder handling challenges such as rat-holing, bridging and blend segregation are solved with the unique Cone Valve design inside each IBC. System solutions are expertly designed to size IBCs to match throughput targets, thereby minimizing manual handling and streamlining operations.

Handling tablets in larger batches has been shown to reduce workload compared to transporting tablets in drums. The portfolio of Matcon tablet IBCs ranges from a simple iris valve to a fully automated cone valve IBC.

Over 40 years the Matcon brand has partnered with leading pharmaceutical brands and generic manufacturers, supplying tailored solutions that optimize workflows for both new facilities & existing process upgrades.

For more information about Matcon's powder handling solutions for the pharmaceutical industry, visit the Matcon brand website via the button below.

The Matcon Product Range

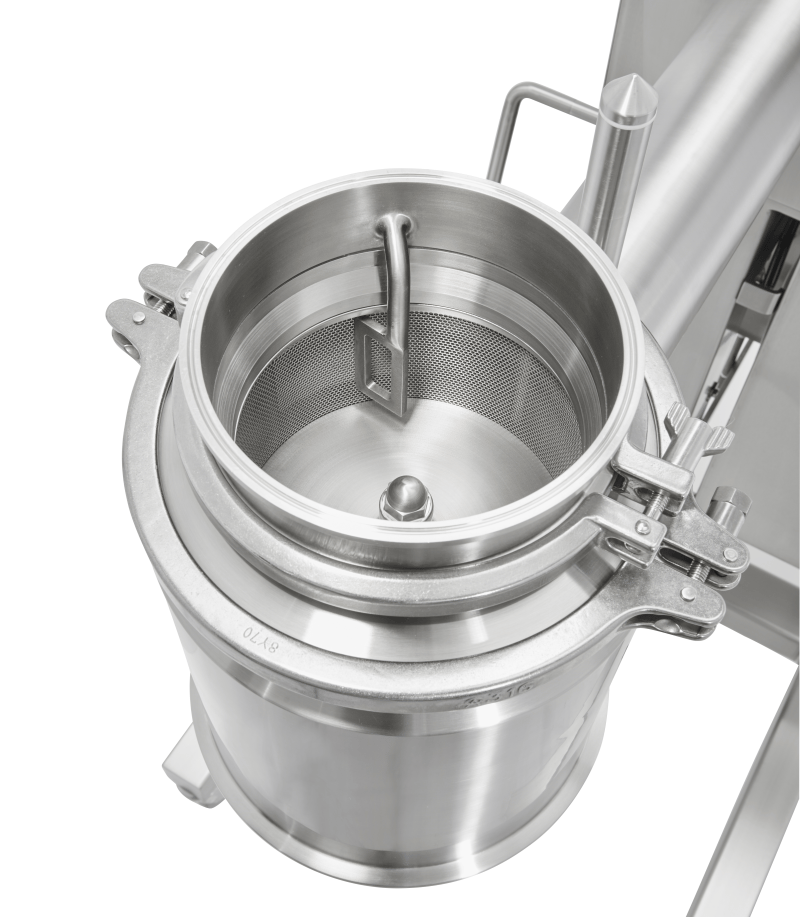

IBCs

Matcon IBCs are efficient, dust-tight powder containers, manufactured to the highest standards in a range of sizes.

Their hygienic design and high containment make them excellent for transporting powders in a pharmaceutical manufacturing facility.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

Tablet Handling

Matcon Tablet IBCs streamline tablet and capsule handling, reducing manual labor and ensuring gentle, damage-free transfer.

Options are available for simple manual IBCs through to fully automated discharge offering efficiency and flexibility.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

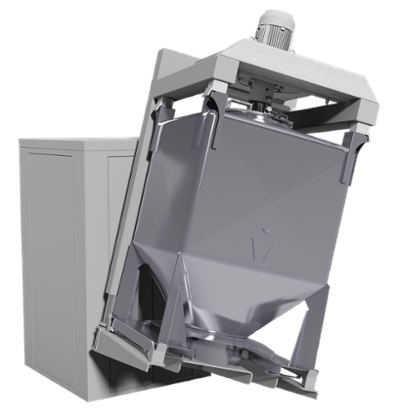

Blending

Tumble blending gently mixes pharmaceutical powders, achieving a blend uniformity (BU) that results in top-quality products.

By using the IBC as the blending vessel, there is no need to clean down between batches, improving flexibility & agility.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.