Food Manufacturing Equipment

Industrial manufacturing equipment for food products, including particle sizing equipment, bulk powder handling, blending, sifting, and screening equipment.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

Powder Handling

Effective handling of the ingredient powders between processing steps is vital to creating an efficient, lean manufacturing line.

Using IBCs not only for transporting materials, but also for blending recipes delivers a flexible and agile factory that can safely handle allergens and make-to-order without compromising down-time.

Particle Sizing

With the combined capabilities of the Quadro & Fitzpatrick brands IDEX MPT is able to deliver milling solutions that are designed to meet particle sizing targets.

The conical mills are ideal for processing delicate ingredients, whilst the hammer mills are more suited to fibrous and tough ingredients.

Sifting & Screening

Efficient screening and sifting ensures that the ingredient powders are conditioned correctly right at the start of the manufacturing process, for quality results throughout.

The inline design and sifting mechanism offers significant capacity improvements compared to traditional vibratory and horizontal sifters.

Why Us

Across IDEX MPT, we are specialists in particle processing for both powders and liquids, offering advanced equipment solutions for leading manufacturers in the food & nutraceutical sectors. Driven by the IDEX values of trust, team, and excellence, our teams utilize critical thinking, creative problem-solving and collaboration to propel our global customers toward their objectives.

Each product in our portfolio is designed and manufactured to the highest standards for materials, finish, and performance. Our equipment is efficient, reliable, and compliant with hygiene standards, so you can trust in our brands for safe, durable solutions that provide lasting value.

Global Coverage

Multiple locations around the world allow us to serve customers globally.

Integrated Teams

The IDEX MPT brands are united to provide you with comprehensive solutions.

Trusted Solutions

Our brands are tested, used & trusted by leading manufacturers worldwide.

Years of Expertise

Many of our brands have been providing manufacturing solutions for over 40 years.

Powder Handling for Food Products

IBC systems for efficient & safe handling of food ingredient powders.

Matcon powder handling systems enable manufacturers to boost production efficiency by streamlining production, reducing changeover times and supporting flexible batch processing. Using IBCs for manufacturing enables shorter production runs, along with fast recipe changeovers, which are ideal for companies with high recipe variety. Make-to-order of variable batch sizes is possible using the IBC in-bin blending capabilities. Safely handle allergens and maintain high hygiene standards throughout the factory.

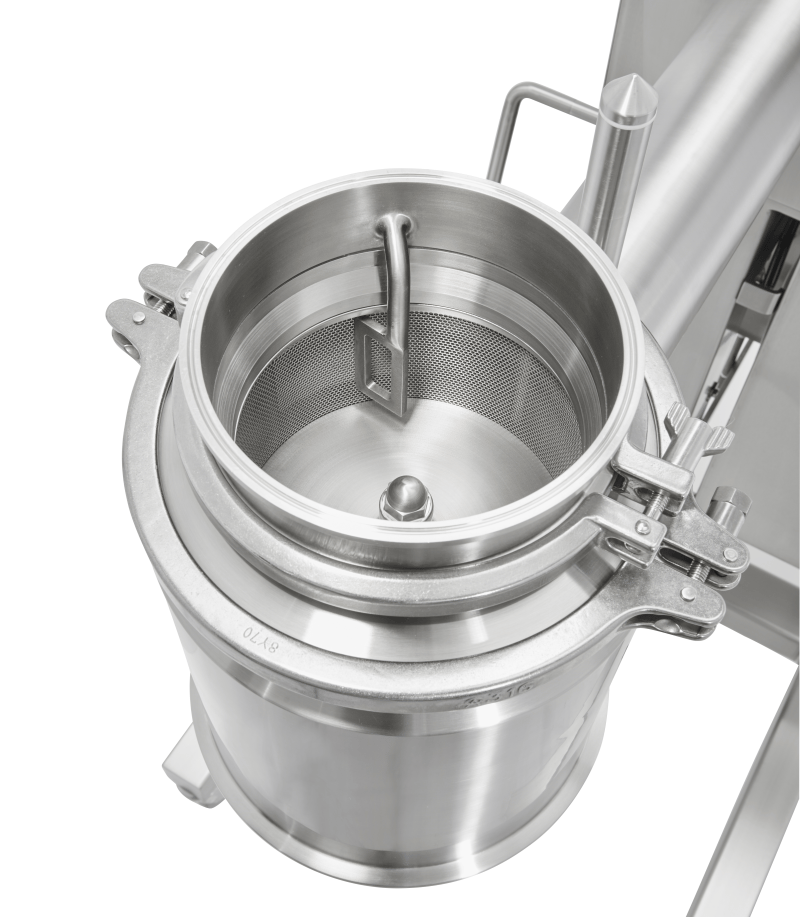

The unique Cone Valve technology within each IBC delivers controlled and reliable powder flow, prevents common problems like rat-holing, bridging and mix separation, that slow down production or impact finished product quality.

With over 40 years of experience partnering with leading food & nutraceutical manufacturers, Matcon delivers tailored solutions that optimize manufacturing workflows in both new facilities or upgrades in existing sites.

For more information about Matcon's powder handling solutions for the food & nutraceutical industries, visit the Matcon brand website via the button below.

The Matcon Product Range

IBCs

Matcon IBCs are efficient, dust-tight powder containers, manufactured to the highest standards in a range of sizes for all industry applications.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

Formulate

Formulate powder recipes directly to IBCs with accurate, automated filling, enabling you to add to your batch processing flow as and when required.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

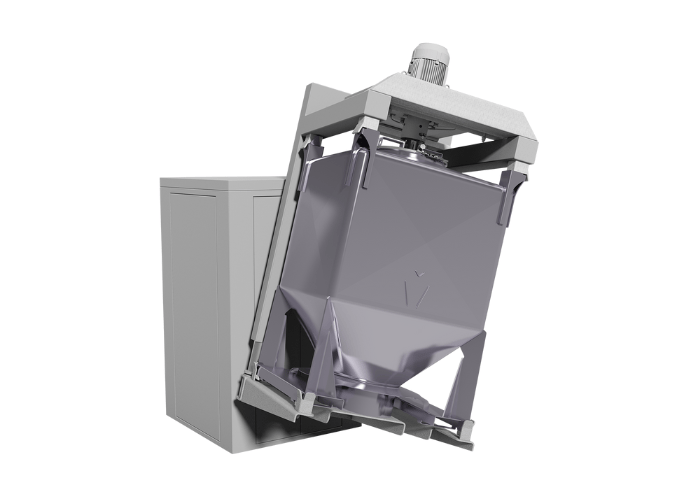

Blend

IBC tumble blending ensures that recipes are mixed effectively and cleaning downtime is significantly reduced, improving operation up-time.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

Pack

Accurately discharge your powder-based products without segregation. Optimize throughput with automated, reliable packing solutions.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

Clean

Remove bottlenecks, cross-contamination and factory downtime with safe, repeatable washing that can be fully automated and performed 'offline'.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

.png?width=232&height=60&name=quadro-logo-blue%20(1).png)

Conical Mills for Food

Gentle milling & sizing solutions for food powders.

Conical mills, also known as cone mills, are well-suited for applications that demand precise, uniform particle sizing and gentle powder handling. Ideal for applications requiring gentle processing, such as processing heat- or shear-sensitive ingredients. Widely chosen in the food industry for the final sizing and screening steps in the manufacturing process, when batch-to-batch consistency and minimal fines are critical.

Quadro mills not only deliver optimal milling for high-value food ingredients, but with a change of screen & impeller they can also be used for the reclaim of off-spec products like cookies & candies, and efficiently break up bulk powders or deagglomerate dried fruit.

Each Quadro® Comil® is designed to meet strict food safety and hygiene standards, ensuring reliable performance and consistent product quality. The portfolio offers a range of solutions that are scalable, user-friendly, and easy to clean, ensuring maximum equipment uptime.

To learn more about Quadro's conical mills for food & nutraceutical products, visit the Quadro brand website via the button below.

Hammer Mills for Food

Hammer milling equipment for food powder size reduction.

Hammer mills are ideal for the size reduction of tougher, more fibrous materials like grains, coffee beans and spices. They are chosen for their robust design, flexible application using knife or bar rotors & different screens, as well as simplicity in design.

Fitzpatrick hammer mills are engineered to deliver efficient and consistent size reduction for a wide range of food powders and ingredients. They deliver precise particle size control while maintaining product integrity, helping food manufacturers achieve uniformity across batches for optimal quality and performance.

The Fitzpatrick brand range of mills help reduce downtime, are straightforward to operate and are designed to be compliant with food safety standards. Whether processing spices, grains, or specialty blends, these mills offer reliable, scalable solutions to meet the rigorous demands of modern food manufacturing.

To learn more about Fitzpatrick hammer mills for the food industry, visit the Fitzpatrick brand website via the button below.

MPT Particle Sizing Equipment

The SDx™ Series

The SDx brings together the milling and sifting technology from Quadro & Fitzpatrick. Simply switch heads to deliver sifting, Conical Milling & Hammer Milling all in one platform.

Available at pilot & production scale, results are directly scalable.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

The G96 Food Mill

Designed for the gentle milling of high value food ingredients, the G96 Food Mill is a cost effective, fast lead time solution for the food sector.

Delivering trusted Comil® performance, the Quadro® G96 Food Mill is purpose-built for precision.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

Fitzpatrick D-Series

The Fitzpatrick D-Series hammer mills are trusted worldwide for efficient, reliable, and high-capacity powder processing.

They are easy to use and can be quickly adapted for different applications with interchangeable parts and screen designs.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

Sifting & Screening Equipment for Food Products

Gentle deagglomeration & sieving of food ingredients.

Quadro’s FlexSift efficiently breaks down agglomerates in powders and removes foreign contaminants from bulk ingredients at the start of the manufacturing process stream.

With an innovative inline design and gentle deagglomeration action, this sifting and screening equipment delivers both efficiency while maintaining particle integrity. The result is safe, high-quality powders ready for further processing or packaging, all while meeting strict hygiene and regulatory standards .

Results have shown significant improvements in capacity compared to traditional vibratory and horizontal sifters. The compact, low profile design of the FlexSift enables easy integration into production lines.

Click the button below to explore Quadro's sifting and screening technology from labscale to production sized.

.png)

The Quadro Flexsift

FlexSift S5

Using the SLS platform fitted with the S5 head, this is the ideal model for testing & research.

Fully scalable results can bring reassurance in concept design.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

FlexSift S10x

On the SDxM platform the S10x head provides small volume or pilot scale screening & sifting.

The greaseless gearbox eliminates the risk of contamination.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.

FlexSift S20x

With the SDx platform the S20x head offers full production capabilities.

Changeovers are made without tooling, bringing efficiencies to the screening & sifting process.

Heading 1

with a request body that specifies how to map the columns of your import file to the associated CRM properties in HubSpot.... In the request JSON, define the import file details, including mapping the spreadsheet's columns to HubSpot data. Your request JSON should include the following fields:... entry for each column.